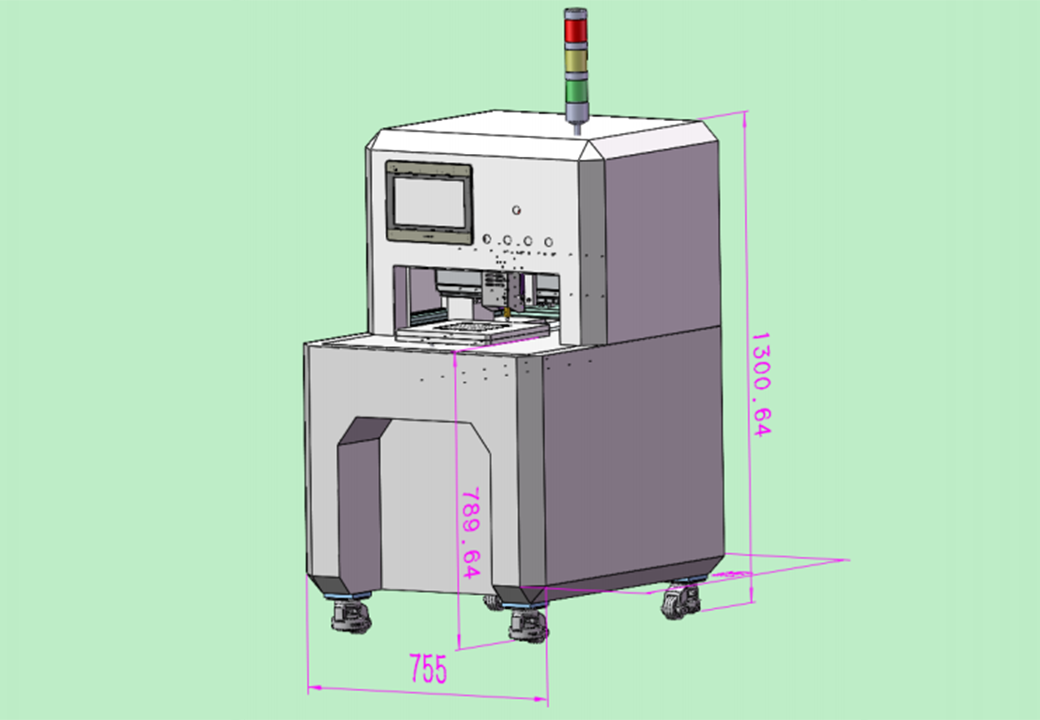

Cell Slide Cutting Machine

1. Technical Parameters:

-

Maximum Cutting Size: 150 x 150 mm

-

Table Size: 300 x 300 mm

-

Cutting Thickness: 0.1 - 2 mm

-

Straight Line Marking Tolerance: ±0.02 - 0.03 mm

-

Machine Weight: Approximately 100 kg

-

Power: 1.7 kW

-

Cutting Speed: 0 - 55 m/min (adjustable)

-

Dimensions: Approximately 755 x 800 x 1350 mm (subject to actual size)

-

Cutting Platform Tolerance: ±0.01 mm

2. Main Configuration:

-

Transmission System: X, Y, and Z axes use Huichuan servo motors

-

Mechanical Configuration: Lead screw and guide rail are Taiwan Hiwin

-

Table: Aluminum table

-

Oil Supply Method: Automatic oil filling device

-

Positioning Device: Mechanical positioning device

-

Bearings: NSK

-

Cutter Head Structure: Pneumatic

3. Electrical Configuration:

-

Pneumatic Components: Japan SMC

-

Electrical Components: Taiwan Shanhe

-

Relays: Taiwan Taian

-

Filters, Solenoid Valves: Japan SMC

-

Switching Power Supply: Omron

-

Buttons, Indicator Lights, Selector Switches: Japan Izumi

-

AC Contactors: Taiwan Taian

-

Air Switches: Taiwan Taian (with leakage protection function)

-

PLC: Inovance

4. Cutting Software (Made by Yinrui):

-

Glass Professional PLC Cutting Software

-

Ability to change the cutting origin position freely

-

Origin correction function

-

Linear layout function

-

Multi-area cutting can automatically optimize the tool path, with many optimization options

-

Blowing and suction conversion (controlled by foot switch)

-

Pause function during cutting

-

100 sets of size memory

-

Information notification for size input errors

-

Cutting original piece count function (daily and monthly production): records the total number only, without distinguishing between days and months

-

Cutting method: Manual setting function

5. Random Delivery:

-

1 set of cutter heads (including: cutter wheel, cutter clamp, small shaft, and copper sleeve)

-

1 set of debugging tools

-

1 system backup

-

1 paper user manual (including software instructions and maintenance instructions)

6. The Buyer Needs to Provide:

-

Power Supply: 3-phase 380V (3 live wires, 1 neutral wire, 1 ground wire)

-

Air Source: 0.4-0.6 MPa dry air source (external φ8 mm air pipe)

7. After-Sales Service: One-year warranty (excluding vulnerable parts and damage caused by human error or environmental factors), with lifelong maintenance.

8. List of Vulnerable Parts:

-

Cutter wheel

-

Copper sleeve

-

Bearing (NSK)

-

Cutter clamp

-

Small shaft

-

Cylinder

-

Synchronous belt

Previous Next