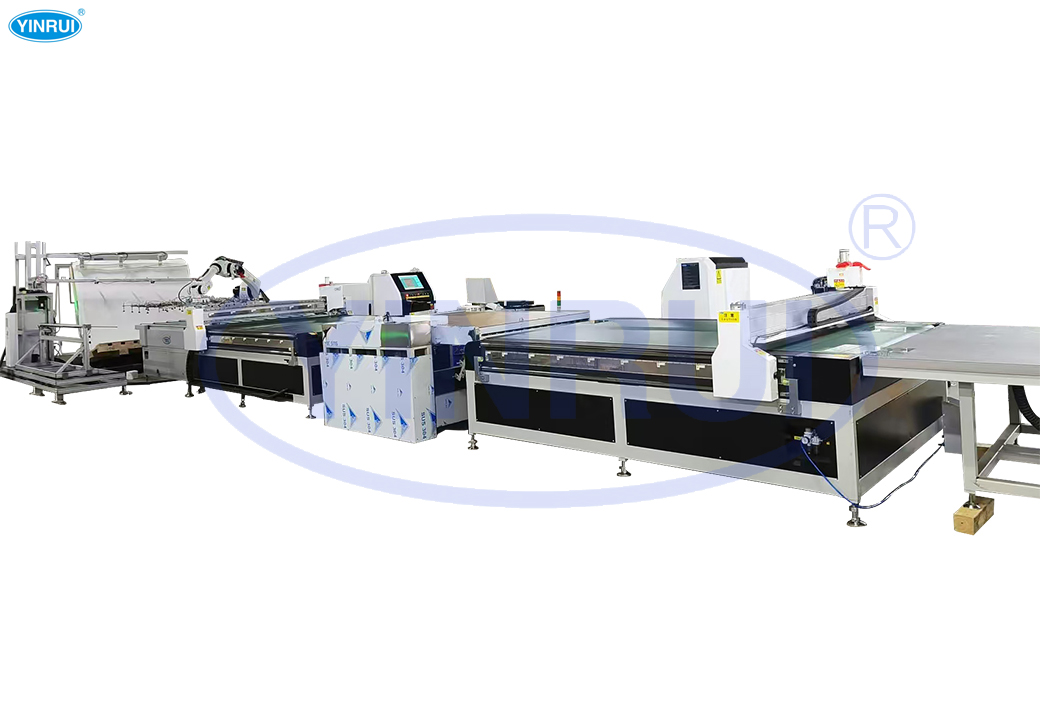

Fully Automatic LCD Glass Double-Sided Cutting Line

1. Equipment configuration list of production line:

|

No.

|

Name

|

Quantity

|

Remarks

|

|

1

|

Glass raw material rack

|

1 piece

|

To be prepared by the customer

|

|

2

|

Loading robot

|

1 piece

|

With paper picking function

|

|

3

|

Paper separator rack

|

1 piece

|

/

|

|

4

|

Glass correction table

|

1 piece

|

/

|

|

5

|

CNC ultra-thin glass cutting machine

|

1 piece

|

Belt transmission type, linear motor configuration

|

|

6

|

Glass flipping machine

|

1 piece

|

/

|

|

7

|

CCD automatic alignment ultra-thin glass cutting machine

|

1 piece

|

Belt transmission type, linear motor configuration

|

|

8

|

Glass breaking table

|

1 piece

|

Manual breaking

|

2. Technical parameters of production line:

No.

|

Name

|

Technical specifications

|

|

1

|

Maximum glass processing specifications

|

2000*1500mm

|

|

2

|

Processing glass thickness

|

0.5-3.0mm

|

|

3

|

Raw material status

|

Double-sided lamination, middle paper

|

|

4

|

Double-sided lamination, middle paper

|

0.05-0.1mm

|

|

5

|

Machine work surface height

|

900±50mm

|

|

6

|

Production line dimensions

|

Approximately 15220mm*3532mm*2500mm (subject to actual size)

|

3. Functional description of single-stage equipment:

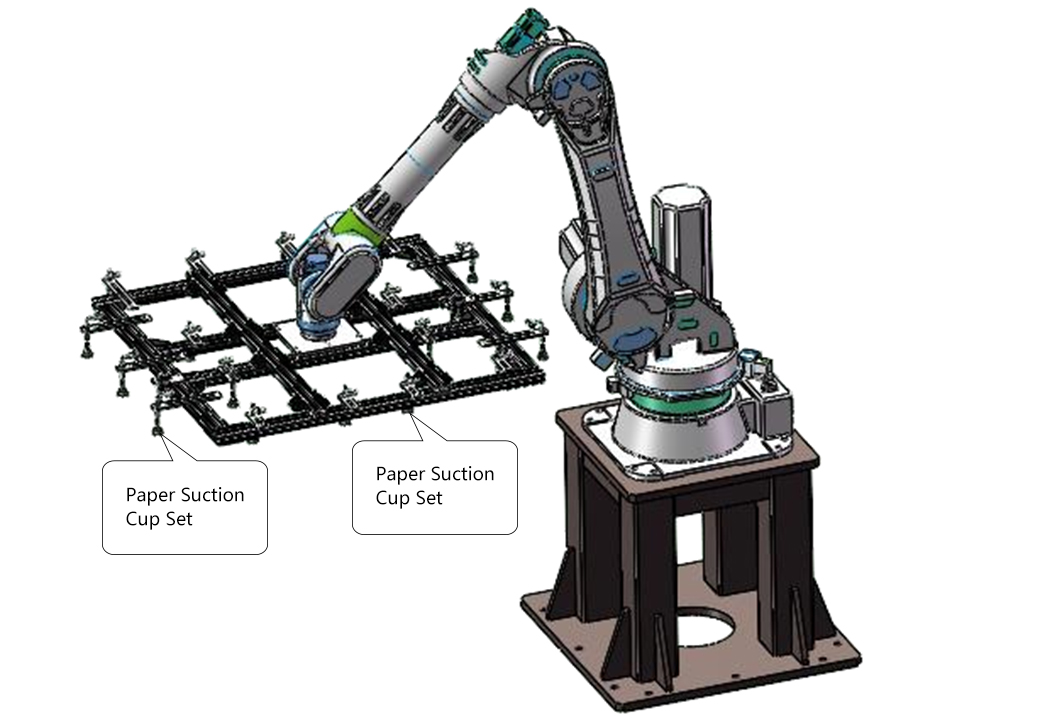

A. Loading robot YRJQR2015

(1). Schematic diagram:

(2) Technical Parameters:

A. Suitable for glass transportation, including a paper picking function;

B. Suitable for glass thickness: 0.5–3 mm;

C. Mechanical arm extension: approximately 2500 mm;

D. Vacuum suction cup for handling glass with the following specifications: 2000 x 1500 mm;

E. Mechanical load: 0–80 kg;

F. Loading cycle: 0–30 seconds.

(3) Electrical Components:

A. Huichuan servo motor, with imported original components;

B. Air switch: Taiwan Taian (with leakage protection function);

C. AC contactor: Taiwan Taian.

(4) Customer Requirements:

A. 0.4–0.6 MPa air supply;

B. Three-phase 380V AC power;

C. Test glass.

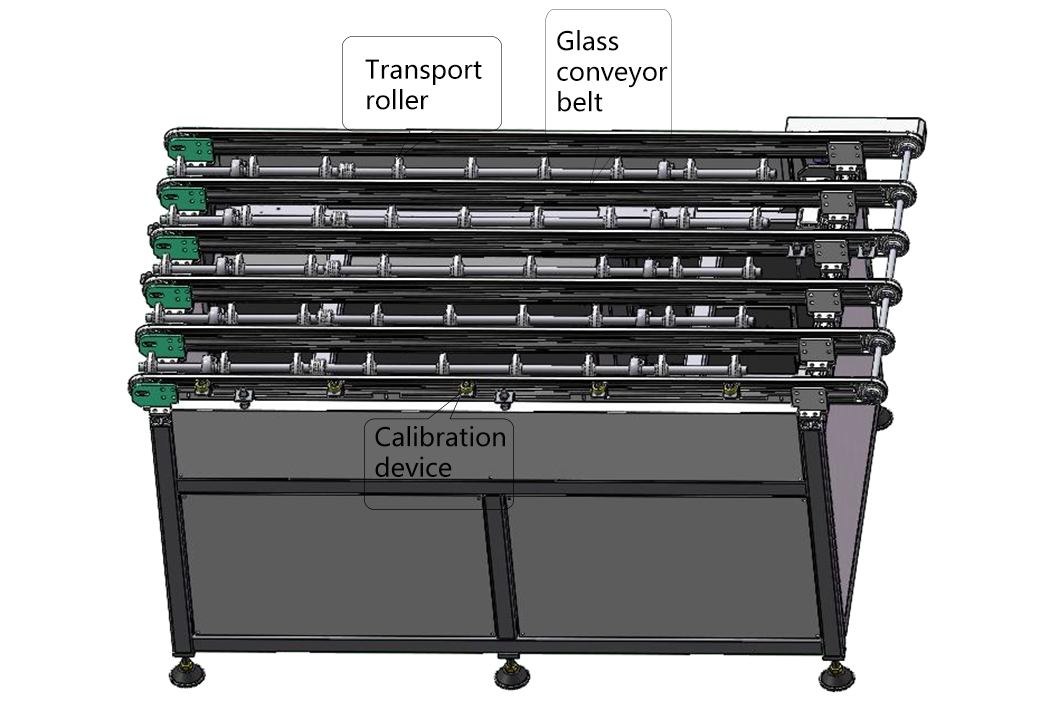

B. Glass Calibration Table YRXZ2015

(1) Schematic Diagram:

(2). Technical parameters:

No.

|

Item

|

Parameter

|

|

1

|

Dimensions

|

Approximately 2200*1800*900mm (subject to actual size)

|

|

2

|

Power

|

1.5kw

|

|

3

|

Voltage

|

3-phase 380V

|

|

4

|

Speed

|

Adjustable

|

(3). Main configuration:

No.

|

Item

|

Configuration

|

|

1

|

Frame

|

National standard steel

|

|

2

|

Conveyor belt, synchronous wheel

|

Customized by Barberi

|

|

3

|

Bearing seat, bearing

|

NSK

|

|

4

|

Conveyor motor

|

Shengbang

|

|

5

|

Optical axis

|

Stainless steel

|

|

6

|

Conveyor roller

|

UPE

|

|

7

|

Sensor

|

Omron

|

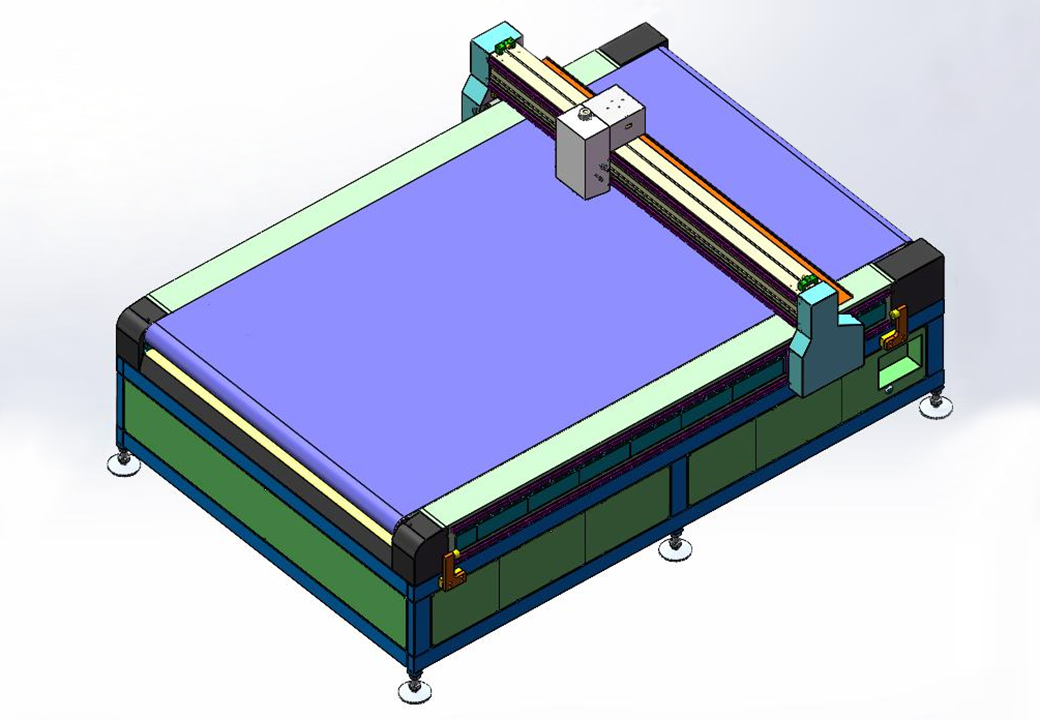

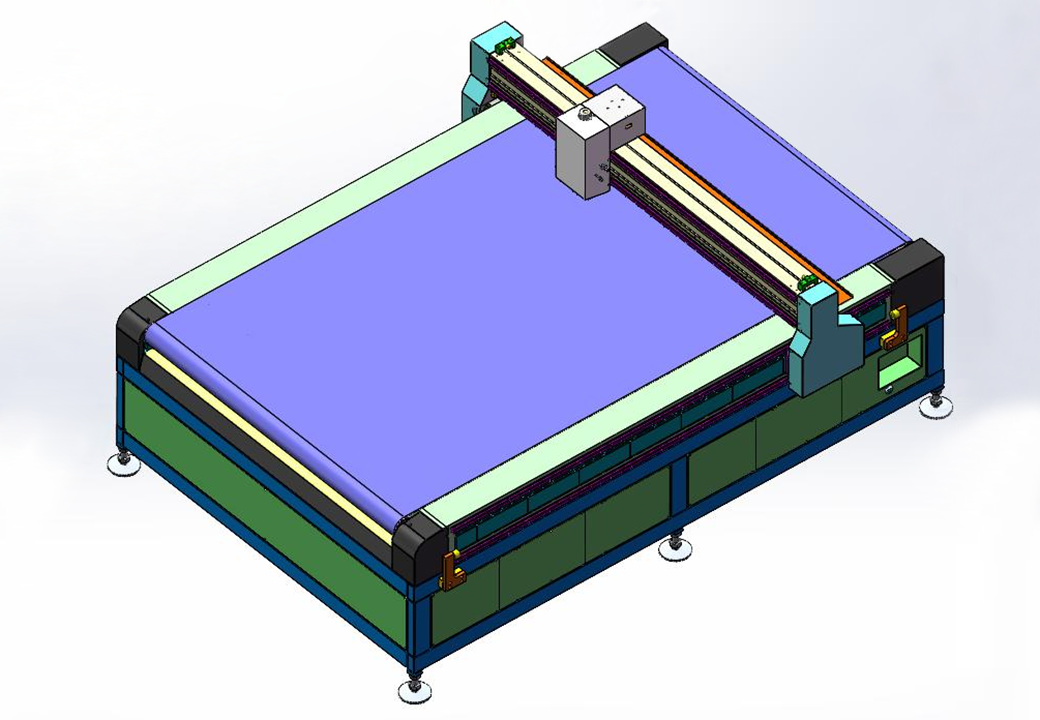

C. CNC ultra-thin glass cutting machine YRDGSCZX2015

(1). Schematic diagram

(2). Technical parameters:

|

No.

|

Item

|

Parameters

|

|

1

|

Cutting glass thickness

|

0.5-3mm

|

|

2

|

Maximum glass cutting size

|

2000*1500mm

|

|

3

|

Cutting stroke

|

2000*1500mm

|

|

4

|

Cutting size

|

Depends on the customer's product size

|

|

5

|

Cutting type

|

Rectangular, circular, special-shaped, etc.

|

|

6

|

Straight line marking accuracy

|

±0.05mm

|

|

7

|

Special-shaped marking accuracy

|

±0.1mm

|

|

8

|

Overall dimensions

|

Approximately 2950*2400*1500mm (subject to actual dimensions)

|

|

9

|

Machine weight

|

Approximately 3800kg (subject to actual weight)

|

|

10

|

Cutting speed

|

0-60 m/min

|

|

11

|

Power

|

Approximately 6kw

|

|

12

|

Beam processing accuracy

|

±0.015mm

|

|

13

|

Knife depth adjustment range

|

10mm

|

(3). Mechanical configuration:

|

No.

|

Item

|

Specification

|

|

1

|

Specification

|

National standard steel, surface treated with baking varnish

|

|

2

|

Transmission system

|

X, Y axis adopts Huichuan linear motor; Z axis adopts Huichuan servo motor

|

|

3

|

Mechanical configuration

|

Sliders and guide rails are made by Taiwan Hiwin

|

|

4

|

Workbench material

|

Precision marble table, including air flotation device

|

|

5

|

Transmission belt

|

Bando (including belt deviation prevention function)

|

|

6

|

Oil supply method

|

Automatic oil filling device

|

|

7

|

Positioning device

|

Automatic edge finding and positioning device, one set of blade limit device

|

|

8

|

Bearing

|

Japan NSK

|

|

9

|

Cutting depth

|

Pneumatic control

|

|

10

|

Belt cleaning

|

With cleaning brush (DuPont nylon wire)

|

|

11

|

Adsorption glass

|

With built-in fan, blowing and suction can be switched freely

|

|

12

|

Cutting method

|

Diamond wheel cutting

|

|

13

|

Tool changing method

|

Manual quick tool changing

|

|

14

|

Table belt transmission can effectively control scratches on glass surface

|

|

15

|

Automatically remove glass chips from the table (with brush)

|

(4). Electrical configuration:

No.

|

Item

|

Brand

|

|

1

|

Pneumatic components

|

SMC

|

|

2

|

Relay

|

Omron

|

|

3

|

Proportional valve

|

SMC

|

|

4

|

Filter, solenoid valve

|

SMC

|

|

5

|

Switching power supply

|

Omron

|

|

6

|

Button, indicator light, selector switch

|

Izumi

|

|

7

|

AC contactor

|

Tai'an

|

|

8

|

Motor circuit breaker

|

Chint

|

|

9

|

Computer configuration

|

ASUS

|

D. Glass turning machine YRFZ2015

(1). Technical parameters:

No.

|

Item

|

Parameter

|

|

1

|

Purpose of equipment

|

Used for 180° turning of glass

|

|

2

|

Dimensions

|

Approximately 2200*2000*1400mm

|

|

3

|

Specifications of processed glass

|

2000*1500mm

|

|

4

|

2000*1500mm

|

0.5-3mm

|

(2). Main configuration:

No.

|

Item

|

Parameter

|

|

1

|

Frame

|

National standard square steel, surface painted

|

|

2

|

Turning frame

|

6061 aluminum

|

|

3

|

Transmission belt

|

PU

|

|

4

|

Bearing seat, bearing

|

NSK

|

|

5

|

Rotating motor

|

Shengbang

|

|

6

|

Conveying motor

|

Shengbang

|

|

7

|

Lifting mechanism

|

SMC cylinder

|

(3). Electrical components:

No.

|

Item

|

Parameter

|

|

1

|

PLC

|

Inovance

|

|

2

|

Touch screen

|

Wei Lun Tong

|

|

3

|

Button, indicator light, selector switch

|

Izumi

|

|

4

|

Sensor

|

Autonics

|

|

5

|

Switching power supply

|

Omron

|

(4). Control system:

No.

|

Name

|

Configuration

|

|

1

|

System

|

Inovance PLC

|

|

2

|

Human-machine interface

|

Weilong touch screen

|

E. CNC visual ultra-thin glass cutting machine YRDGSCZX2015

(1). Schematic diagram:

(2). Technical parameters:

No.

|

Item

|

Parameter

|

|

1

|

Cutting glass thickness

|

0.5-3mm

|

|

2

|

Maximum glass cutting size

|

2000*1500mm

|

|

3

|

Cutting stroke

|

2000*1500mm

|

|

4

|

Cutting size

|

Depends on the customer's product size

|

|

5

|

Cutting type

|

Rectangular, circular, special-shaped, etc.

|

|

6

|

Straight line marking accuracy

|

±0.05mm

|

|

7

|

Special-shaped marking accuracy

|

±0.1mm

|

|

8

|

Overall dimensions

|

Approximately 2950*2400*1500mm (subject to actual dimensions)

|

|

9

|

Machine weight

|

Approximately 3800kg (subject to actual weight)

|

|

10

|

Cutting speed

|

0-60 m/min

|

|

11

|

Power

|

Approximately 6kw

|

|

12

|

Beam processing accuracy

|

±0.015mm

|

|

13

|

Knife depth adjustment range

|

10mm

|

(3). Mechanical configuration:

No.

|

Item

|

Specification

|

|

1

|

Frame

|

National standard steel, surface treated with baking varnish

|

|

2

|

Transmission system

|

X, Y axis adopts Huichuan linear motor; Z axis adopts Huichuan servo motor

|

|

3

|

Mechanical configuration

|

Sliders and guide rails are Taiwan Hiwin

|

|

4

|

Tabletop

|

Marble precision tabletop, including air flotation device

|

|

5

|

Transmission belt

|

Bando (including belt deviation prevention function)

|

|

6

|

Oil supply method

|

Automatic oil filling device

|

|

7

|

Positioning device

|

Automatic edge finding positioning device, a set of blade limit devices

|

|

8

|

Bearing

|

Japan NSK

|

|

9

|

Cutting depth

|

Pneumatic control

|

|

10

|

Belt cleaning

|

With cleaning brush (DuPont nylon wire)

|

|

11

|

Adsorption glass

|

With built-in fan, blowing and suction can be switched freely

|

|

12

|

Cutting method

|

Diamond wheel cutting

|

|

13

|

Tool changing method

|

Manual quick tool changing

|

|

14

|

Table belt transmission can effectively control scratches on glass surface

|

|

15

|

Automatically remove glass chips from the table (with brush)

|

(4). Electrical configuration:

No.

|

Item

|

Brand

|

|

1

|

Pneumatic components

|

SMC

|

|

2

|

Relay

|

Omron

|

|

3

|

Proportional valve

|

SMC

|

|

4

|

Filter, solenoid valve

|

SMC

|

|

5

|

Switching power supply

|

Omron

|

|

6

|

Button, indicator light, selector switch

|

Izumi

|

|

7

|

AC contactor

|

Tai'an

|

|

8

|

Motor circuit breaker

|

Chint

|

|

9

|

Computer configuration

|

ASUS

|

Previous Next