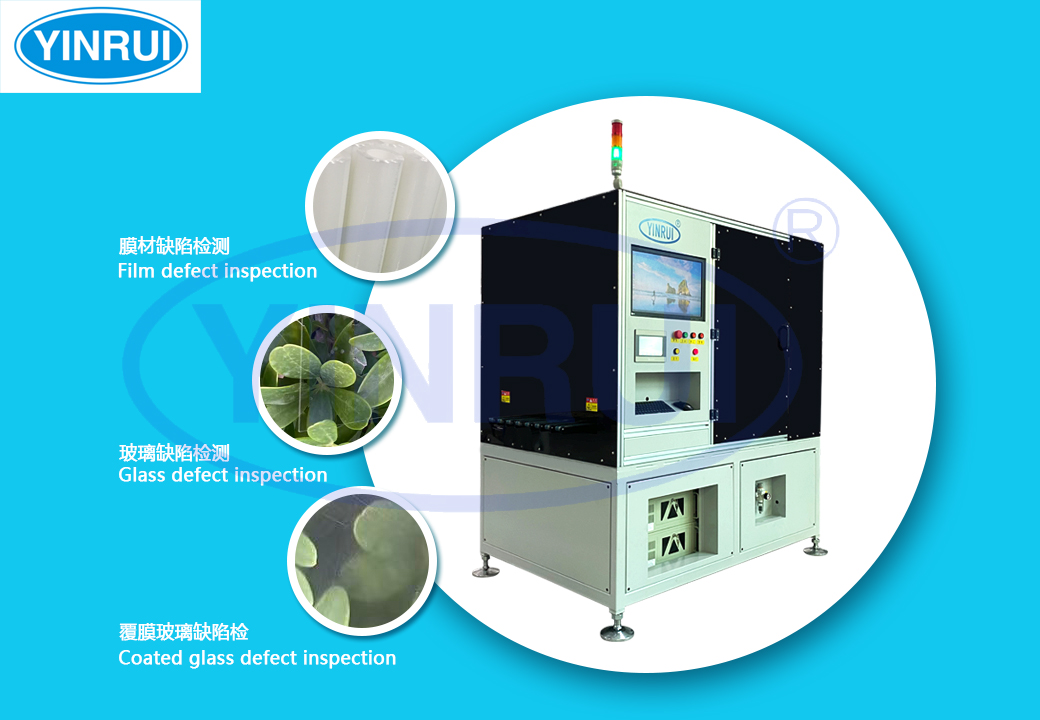

Smart Vision Laminated Glass Inspection Equipment

Laminated Glass Defect Inspection Machine

High-Precision AOI System for Laminated Glass

The Laminated Glass Defect Inspection Machine is an advanced AOI (Automatic Optical Inspection) system designed for real-time detection of surface, edge, and coating defects in laminated glass, including automotive laminated glass, display laminated glass, and safety laminated glass.

Equipped with high-resolution cameras and intelligent vision algorithms, the system accurately identifies scratches, bubbles, delamination, cracks, stains, and coating defects, enabling precise micro-defect detection on transparent or semi-transparent laminated glass.

With a high-speed image processing platform and automatic defect classification software, this machine delivers stable, accurate, and efficient inspection results, significantly improving yield and quality control in laminated glass production and processing.

Key Features

-

High-Resolution Optical Cameras for micro-defect detection

-

AI-Based Intelligent Algorithms for automatic defect recognition and classification

-

Supports Multiple Laminated Glass Types: automotive, display, safety, and coated laminated glass

-

Real-Time Inspection and Data Recording for process optimization

-

Modular Design for integration into production lines or standalone operation

Applications

-

Automotive laminated glass production inspection

-

Display and touch panel laminated glass quality control

-

Safety laminated glass defect detection

-

Coating and lamination process quality monitoring

Previous Next