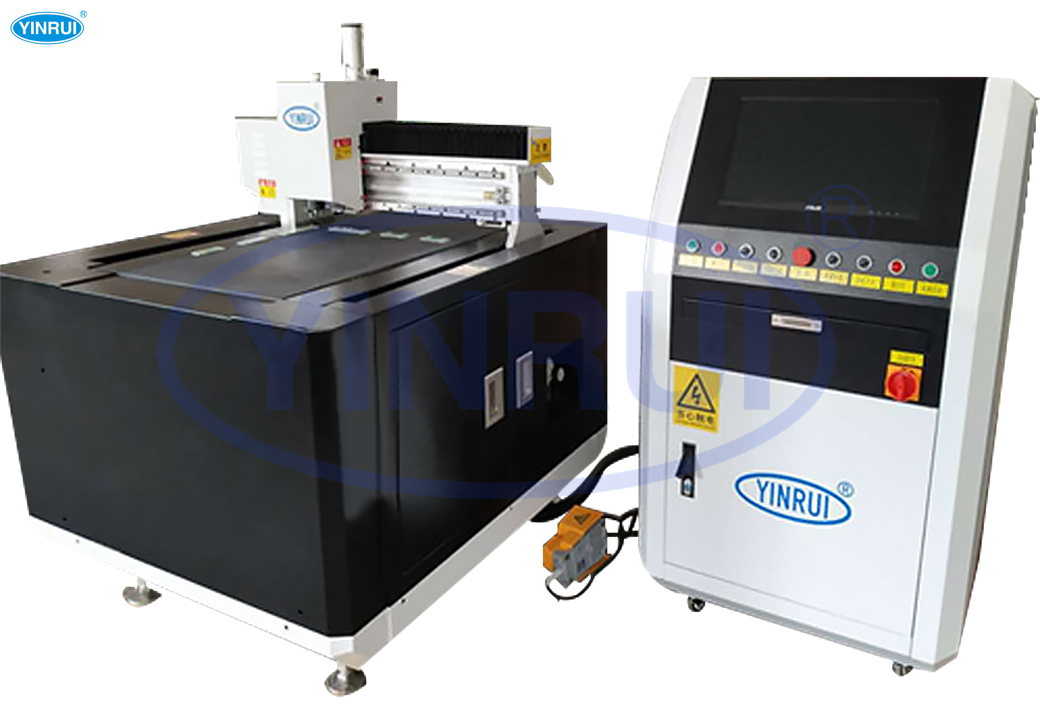

Optical Glass Cutting Machine

1. Technical Parameters:

-

Machine Dimensions: 1400 x 1229 x 1350 mm

-

Maximum Original Sheet Size: 600 x 550 mm

-

Minimum Cutting Size: 10 x 10 mm

-

Cutting Thickness: 0.1 to 5 mm

-

Straight Line Marking Tolerance: ±0.025 mm

-

Special-Shaped Marking Tolerance: ±0.05 mm

-

Marble Precision Table Surface Accuracy: ±0.015 mm

-

Beam Processing Accuracy: ±0.015 mm

-

Cutting Speed: 0 to 100 m/min

-

Machine Weight: 800 kg

-

Power: 2.1 kW

2. Cutting Software (Developed by Yinrui):

-

The software includes a processing wizard with options for straight-line cutting, circular cutting, area cutting, and more, offering a variety of standard patterns.

-

CAD drawing capability, allowing for the cutting of rectangles and various shapes.

-

The cutting origin position can be adjusted freely.

-

Multi-area cutting function optimizes the tool path and allows for changes in the tool path sequence.

-

Blowing and suction conversion function (controlled by foot switch or automatic suction during cutting).

-

Pause function during cutting.

-

Cutting pressure and speed ratio adjustment function.

-

Cutting piece counting function.

-

Cutting pressure library function.

-

Single cutting program timing function.

-

Dimension input error notification function.

-

Cutter head eccentricity correction function.

-

Three cutting modes: direct cutting, stand-alone, and online.

-

Manual and automatic mode switching function.

-

Cutter wheel and arbor life tracking and warning function.

-

The pressure and speed can be adjusted individually for each cutting path.

3. The Purchaser Needs to Provide:

Power Supply: 3-phase, 380V, 50Hz (3 live wires, 1 neutral wire, 1 ground wire).

Air Source: 0.4-0.6 MPa dry air source (external φ8mm air pipe).

4. After-Sales Service:

One-year warranty (excluding vulnerable parts and damage caused by human error or environmental factors); lifetime maintenance.

5. IX. List of Vulnerable Parts:

Diamond cutter wheel, copper sleeve, bearing (NSK), cutter clamp, cutter shaft, synchronous belt, cylinder, etc.

Previous Next