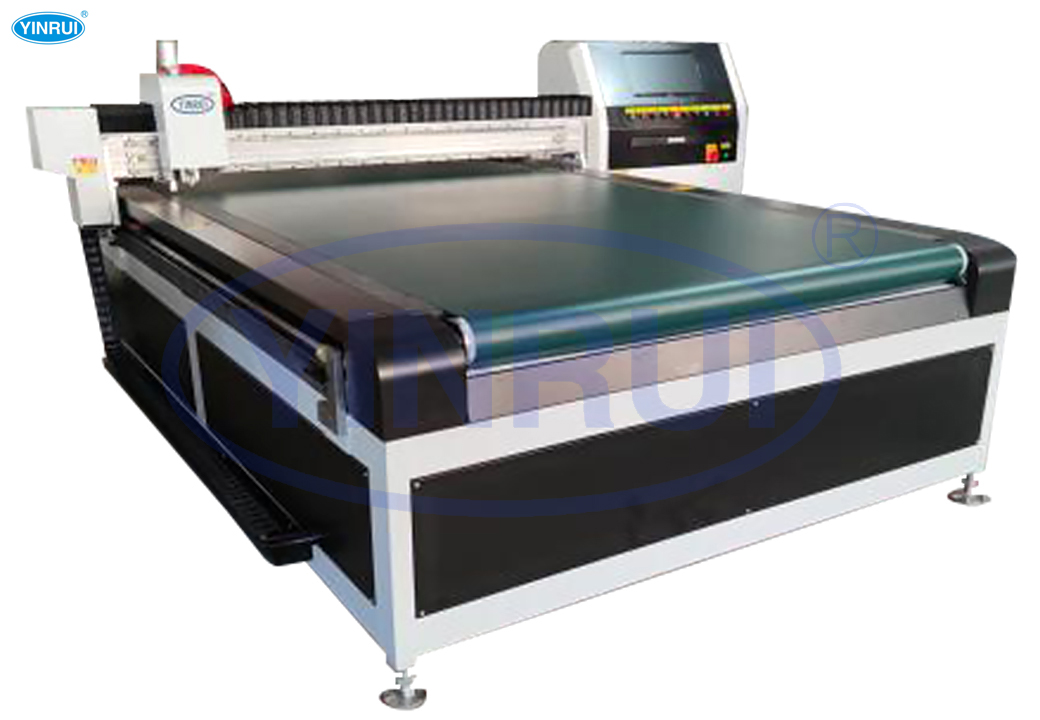

CNC Transmission-Type Ultra-Thin Glass Cutting Machine for Covers

1.Technical Parameters:

-

Cutting Thickness: 0.3–5 mm

-

Effective Cutting Size: 2000 × 1540 mm

-

Minimum Glass Cutting Size: 370 × 470 mm

-

Overall Dimensions: 2965 × 2300 × 1500 mm (excluding control box)

-

Machine Weight: 3500 kg

-

Straight Line Cutting Tolerance: ±0.05 mm (within 250 mm), ±0.07 mm (within 500 mm), ±0.1 mm (above 500 mm)

-

Marble Precision Table Surface: ±0.015 mm

-

Cutting Speed: 0–75 m/min (adjustable)

-

Power: 6 kW

-

Beam Processing Accuracy: 0.015 mm

-

Knife Depth Adjustment Range: 10 mm

-

Conveyor Belt Level: ±0.015 mm (Japan Bando belt)

2. Mechanical Configuration:

-

Transmission System: The X, Y, and Z axes use Delta imported servo motors (dual-drive structure).

-

Oil Supply Method: Automatic oil filling device.

-

Positioning Device: Automatic edge positioning device and a set of tool head limit devices.

-

Mechanical Components: Lead screw is Hiwin; guide rail is Taiwan Hiwin.

-

Table: Marble precision table, including air flotation device.

-

Bearings: Japan NSK.

-

Table Belt Transmission: Effectively controls scratches on the glass surface.

-

Automatic Glass Chip Removal: The table automatically removes glass chips (with brush).

-

Dust Collection System: A set of dust collection devices.

3. Delivery List:

-

1 Glass Breaking Table

-

1 Set of Cutter Heads (including: cutter wheel, cutter holder, small shaft) and 1 Copper Sleeve

-

1 Set of Debugging Tools

-

1 Software Backup

-

1 System Backup

-

1 User Manual (including software instructions and maintenance instructions)

Previous Next