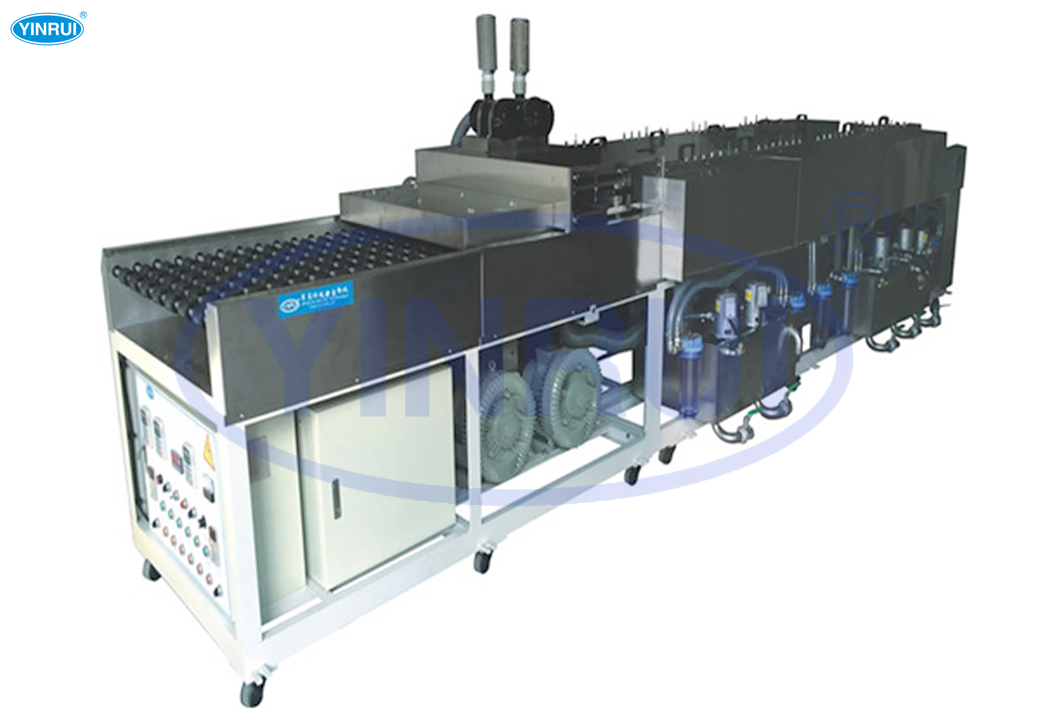

Air Blade Glass Cutting Machine

1. Equipment Size: 5290 (L) × 1900 (W) × 1400 (H) mm

2. Cleaning Process Flow:

Feeding → spray washing → liquid brush washing 1 → wind knife liquid cutting → DI spray brush washing 1 → DI spray brush washing 2 → pure water washing 3 → two sets of wind knife drying → drying → static elimination → discharging

3. Conveying Height: 950 mm (adjustable ±30 mm)

4. Cleaning Speed: 1–4.5 m/min (adjustable); cleaning direction: right to left as viewed from the operating side

5. Glass Cleaning Method:Feeding: C/V Discharging: C/V

6. Cleaning Glass Specifications:Dimensions: 150 × 70 mm to 500 × 500 mm Thickness: 0.4–4.0 mm Placement Style: Parallel placement

7. Electric Control Box: Independent electric cabinet with touch screen control

8. Equipment Composition and Structure Specifications:

(1) Feeding:

Working Length: 543 mm

Pipeline: DN40

Four-Channel Guide Plate: Made of PVC material

Conveyor Roller: Includes one set of emergency switches (for stopping and starting motor drive)

(2) Spray Washing:

-

Working Length: 387 mm

-

Spray Structure:

-

Nozzle: PP umbrella nozzle

-

Pressure: 1–1.5 kg/cm²

-

Flow Rate: 1.5 L/min

-

Nozzle Material: PVC (4 pieces; 2 pieces each for upper and lower parts)

-

Pressure Gauge:

-

Operating Range: 0–4 kg/cm²

-

Quantity: 1 piece

-

Nozzle Pump: "Nanfang" stainless steel pump, 0.55 kW (1 piece)

-

Filter:

-

Material: PVC

-

Specification: 250 mm × 1 core (1 set)

-

Filter Accuracy: 10 μm

-

Temperature Control System:

-

Heater: 5.5 kW/piece (SUS304)

-

Temperature Control: E5CZ-R2PT100, adjustable and calibrated (maximum operating temperature: 60°C)

(3) DI Water Brush Cleaning 1, 2, 3:

-

Working Length: 520 mm, 530 mm, 470 mm

-

Spray Structure:

-

Nozzle: PP umbrella nozzle

-

Pressure: 1–1.5 kg/cm²

-

Flow Rate: 1.5 L/min

-

Nozzle Material: PVC (6 pieces; 3 pieces each for upper and lower spray pipes)

-

Pressure Gauge: Operating range: 0–4 kg/cm² (4 pieces; 1 piece each for upper and lower spray pipes, 1 piece each for the front and rear of the filter)

-

Arrangement: 4/5 pieces

-

Nozzle Pump: "Nanfang" stainless steel pump, 0.55 kW (3 pieces)

-

Filter:

-

Material: PVC

-

Specification: 250 mm × 1 core (1 set)

-

Filter Accuracy: 10 μm

-

Brush Device:

-

Brush Motor: 200 W (3 pieces)

-

Brush Speed: 100–450 ±50 rpm (inverter speed control)

-

Brush Wheel:

-

Material: US DuPont nylon thread (NL66, φ0.1 mm)

-

Specifications: φ65 × 450 mm

-

Roller Brush Wheel Arrangement: Upper and lower brushes; 12 in total

-

Drive Mode: Synchronous belt

(4) Pure Water Flushing:

Working Length: 405 mm

-

Spray Structure:

Nozzle: PP umbrella nozzle

-

Pressure: 1–1.5 kg/cm²

-

Flow Rate: 1.5 L/min

-

Nozzle Material: PVC (4 pieces; 2 pieces each on the top and bottom)

-

Pressure Gauge: Operating range: 0–4 kg/cm² (1 piece)

-

Arrangement: 5 pieces

-

Water Source: Provided by the customer (solenoid valve automatically replenishes water)

-

Filter:

Material: PVC

-

Specifications: 250 mm × 1 core (1 set)

-

Filter Accuracy: 5 μm

(5) Three-Set Wind Knife Wind Cutting Drying:

(6) Drying and Static Elimination:

-

Working Length: 750 mm

-

Structure:

Infrared Radiation: 3 kW, 6 lines

-

Static Elimination: 5 kW × 1 unit

-

Filter System: Primary, medium, and high-efficiency filters (1 set)

(7) Discharging:

-

Working Length: 885 mm

-

Configuration:

Includes 1 set of emergency switches (for stopping and starting motor transmission)

Previous Next